In 3D printing, particularly in technologies such as Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF), the quality of the final product is heavily dependent on the effectiveness of the fusing process. Fusing lamps and infrared (IR) heaters play a crucial role in this process by providing the necessary heat to fuse powder materials into solid objects. These components ensure that the materials are sintered or melted accurately and consistently, contributing significantly to the structural integrity and detail of printed items. This article explores the functionality, importance, and maintenance of fusing lamps and IR heaters, highlighting their role in enhancing the efficiency and quality of 3D printing operations.

Importance of Fusing Lamps and IR Heaters in 3D Printing

Efficient Material Processing: Fusing lamps and IR heaters enable rapid and uniform heating of the powder bed, ensuring that materials are processed efficiently and within the optimal temperature range for sintering or melting.

Enhanced Print Quality: Uniform heating is essential for achieving high-quality prints with excellent mechanical properties and minimal defects such as warping or porosity.

Energy Efficiency: Modern fusing lamps and IR heaters are designed to maximize energy use, reducing operational costs and enhancing the sustainability of the printing process.

Control and Precision: These components allow for precise control over the heating process, which is crucial for working with advanced materials that require specific thermal conditions.

Components of Fusing Lamps and IR Heaters in 3D Printers

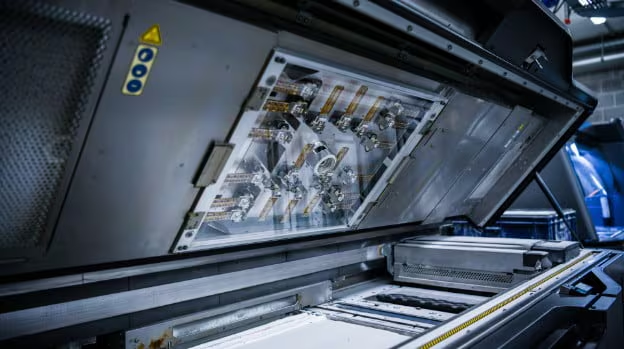

Heating Elements: In IR heaters, these elements emit infrared radiation that penetrates the powder material, causing it to heat up and fuse. Fusing lamps, often halogen or quartz, provide a broad spectrum of light, including infrared, to efficiently melt the material.

Reflectors and Optics: These are used to direct and focus the heat or light onto the specific areas of the powder bed, ensuring even distribution and minimizing heat loss.

Thermal Insulation: To prevent heat from escaping and to maintain a consistent temperature within the build chamber, effective insulation is crucial.

Temperature Sensors and Controls: These components monitor the temperature of the powder bed and adjust the output of the heaters or lamps to maintain the desired thermal conditions.

Cooling Systems: To prevent overheating of the components and the build area, cooling systems are often integrated into printers with high-power fusing lamps or IR heaters.

Installation and Calibration of Fusing Lamps and IR Heaters

Proper Installation: Ensuring that fusing lamps and IR heaters are correctly installed is critical for their effective operation. This includes securing them in the right position to uniformly cover the build area and integrating them with the printer’s control systems.

Calibration: Regular calibration is necessary to maintain the accuracy of the temperature controls and sensors. Calibration involves checking and adjusting the sensors and controls to ensure they respond correctly to temperature changes in the build chamber.

Testing: Before starting full-scale production, it is essential to test the heating system to verify that it can consistently reach and maintain the required temperatures across the entire build platform.

Maintenance and Optimization of Fusing Lamps and IR Heaters

Regular Cleaning: Keeping the lamps, heaters, reflectors, and surrounding areas free from powder and debris is crucial for maintaining their efficiency and preventing fire hazards.

Component Inspections: Regularly inspecting the lamps, heaters, and associated electrical components for signs of wear or damage is crucial. This includes checking for burnt-out lamps or failing elements.

Reflectors and Optics Maintenance: Clean and check reflectors and optics to ensure they are not damaged or misaligned, which can affect the focus and distribution of heat.

Thermal Calibration Checks: Frequent checks and recalibration of thermal sensors and temperature controls help in maintaining precise control over the fusing process.

Challenges and Solutions

Heat Distribution: Achieving uniform heat distribution can be challenging, especially in large build chambers. Using multiple heating elements and optimizing their placement can help overcome this issue.

Energy Consumption: High-power heaters can consume significant amounts of energy. Optimizing the cycling and power output of the heaters can reduce energy use without compromising print quality.

Component Lifespan: High temperatures and frequent heating cycles can reduce the lifespan of heating elements. Implementing predictive maintenance and using high-quality, durable components can help extend their operational life.

Fusing lamps and infrared heaters are integral components of 3D printing systems that require thermal processing of materials. They play a vital role in ensuring the efficiency, quality, and reliability of the printing process. Proper management, regular maintenance, and careful calibration of these components are essential for maximizing the performance of 3D printers and ensuring the production of high-quality printed products. Understanding and optimizing the function and maintenance of fusing lamps and IR heaters can lead to significant improvements in the operational reliability and quality of 3D printed items, enhancing both productivity and material properties.